What are Portal Frames?

Columns and horizontal rafters are normally attached by moment-resisting connections to form portal frames, which are generally low-rise structures. The bending stiffness of the members and the rigidity of the connections provide resistance to lateral and vertical actions, which can be augmented by haunching or deepening the rafter sections.

In this structure, the plane of the frame remains stable, and there is a clear span unobstructed by bracing. 50% of construction steel in the UK is used during the construction of portal frames, making them a very common building type.

As they’re very efficient to construct over a large area and provide a large coverage and are used in sectors that need cost-efficient coverage, such as industrial and storage units, as well as commercial and retail units.

In this article, we go into more detail about the construction of portal frame buildings:

Steelgram Fabrications also offer a Portal Frames service in the UK here.

Types of Portal Frame Buildings

The various portal frame types described below provide an idea of the types of portal construction available.

Each of the typical features have been illustrated. This information is not intended to dictate limits on structural forms, rather just give you a realistic idea of the uses of each.

Portal frame featuring a mezzanine floor

Often office accommodation sits within a steel portal frame structure that utilises the use of a mezzanine floor.

The assessment of frame stability needs to demonstrate the effect of the mezzanine floor; guidance is provided in SCI P292.

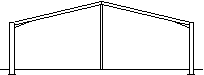

Pitched roof symmetric portal frame

These frames are usually fabricated from UB sections with a large eaves haunch section cut from a fabricated plate or rolled section. 25 to 35 m are the most effective and common spans.

Crane portal frame featuring column brackets

In the case where a travelling crane of up to 20 tonnes is required, brackets can be attached to the columns of the frame to support the crane rails. By using a tie member or rigid column base, this reduces the eaves deflection.

The spreading of the frame at the crane’s level is critically important to how the crane functions overall. Requirements should be agreed with the client prior to construction along with consent from the crane manufacturer too.

Tied portal frame

The horizontal movement of the eaves present in a tied portal frame along with bending motions in the columns are significantly reduced. Tie portal frames can be highly effective in limiting the spreading of a crane-supported structure.

Because of the high axial forces that are introduced to the frame where a tie is used, the use of second-order software should be necessitated to analyse its overall form.

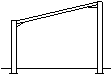

Mono-pitch portal frames

Mono-pitch portal frames are generally used for small spans and because of their proximity to other buildings in the area. As a simplistic variation of the pitched roof portal frame, these frames tend to be ideal for smaller constructions of up to 15m span.

Propped portal frame

In the case where the span of the portal frame is larger than usual and you don’t have to provide a clear span, a propped portal frame is suitable. This reduces the size of the rafters along with the horizontal shear present at foundation level.

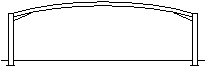

Mansard portal frame

Mansard portal frames are generally chosen in the case of large and clear height mid-spans where the eaves height of a building is minimised in comparison.

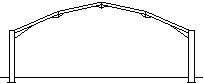

Curved rafter portal frame

Portal frames can be constructed with curved rafters which are implemented generally for architectural reasons. Due to transport limitations however, rafters that are longer than 20m usually require splices. Curved members are usually modelled for analysis based on a series of straight elements and stability of curved rafters within portal frames of this type is provided in SCI P281.

As an alternative, curved rafters can also be created using a series of straight rafters. However, in doing so, it’s a necessity that purlin cleats of various heights are provided in order to achieve a curved profile for the rafters.

Cellular beam portal frame

Rafters can be fabricated using cellular beams and this is usually the case for aesthetics. However, they may also be preferred for long spans and where transportation is limited which imposes a requirement for the use of splices. They should be carefully detailed in order to preserve their architectural features and be of an elastic design.

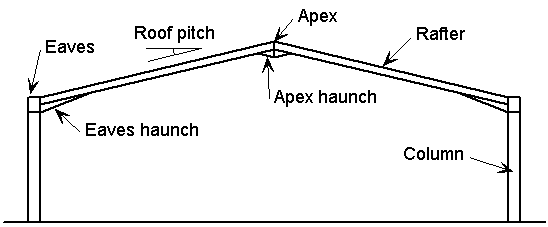

Portal frame anatomy

Buildings with portal frames are made up of transverse frames that are braced longitudinally. Portal frames and bracing are formed by columns and rafters. There are two types of end frames (gable frames): portal frames and braced arrangements of columns and rafters.

Secondary steelwork consists of side rails for walls and purlins for roofs. Primary steelwork is resisted by secondary steelwork, which supports the building envelope.

Cladding is used in the walls and the roof to provide a good thermal and acoustic barrier from the outside of the building. A cladding’s structural purpose is to transfer loads to secondary steelwork and to restrain the flange of a purlin or rail to which it is attached.

Considerations in design

It is important to consider a large number of interrelated design requirements at every stage of the design process in the design and construction of any structure. This discussion of the design process and its constituent parts is intended to provide the designer with an understanding of the relationship between the structural elements and the final construction of the structure, so that decisions can be made based on a clear understanding of the implications at each stage.

Section and material choice

Portal frame structures are usually made of S355 steel sections. For plastically designed portal frames, Class 1 plastic sections must be used at hinge positions that rotate, while Class 2 compact sections can be used elsewhere.

Dimensions of the frame

At the conceptual design stage, the height and width of the frame are crucial to ensure adequate internal dimensions and clearance for the building’s functions.

Dimensions of the clear span and height

Dimensions should be established early in the design process based on the clear span and height required by the client. It is likely that the client will require the clear distance between the flanges of the two columns. Therefore, the span will be larger because of the section depth. As the design span may be affected by brickwork or blockwork around the columns, it should be determined whether brickwork or blockwork is needed around the columns.

In the case of clear internal heights, these are usually measured from the finished floor level to the underside of the haunch or suspended ceiling.

The main frame

In general, the main (portal) frames are made from UB sections with a substantial eaves haunch section, either rolled or fabricated from plate. Characteristics of a typical frame include:

- Spans between 15 and 50 m

- The clear height of the haunch should be between 5 and 12 metres

- Roof pitches between 5° and 10° (though 6° is commonly used)

- 6 to 8 m spacing between frames

- Haunches present between the rafters at the eaves and apex

- An approximate stiffness ratio of 1.5 between the column and rafter sections

- Light gauge purlins and side rails

- Light gauge diagonal ties between some purlins and the side rails in order to restrain the interior flange of the frame at certain points

Dimensions of the haunch

Where a haunch is used, its dimensions are critical. A haunch will reduce the required depth of any rafter by increasing the moments resistances of the member where applied moments are at their highest.

The haunch will also add stiffness to the portal frame which will reduce any deflections and it helps to facilitate a sturdy bolted moment connection too.

Eaves haunchers are typically cut out from the same sized rolled section that the rafter is. It may also be cut from one that is slightly bigger. Once cut, it is welded onto the underside of a rafter and its length generally equates for 10% of the total frame span.

A haunch length is calculated by looking at the hogging moment at its end which is equal to the largest sagging moment at the apex. Its depth from the rafter axis to the underside of the haunche equates for 2% of the total span.

An apex haunch can be cut directly from a rolled section which is the same size as the rafter or alternatively made from plate. The apex haunch isn’t usually modelled as part of the frame analysis and is only used in order to facilitate a bolted connection within the frame.

Restraint positioning

At the initial design phase, the rafter members are selected in accordance with their cross-sectional resistance to bending moments and axial force. During the later design phases, stability in relation to buckling should be verified and restraints positioned with good judgement.

Selection of the column size plays a big part in buckling resistance as there generally is much less freedom in terms of positioning the rails to align with the design’s requirements. This means that the rail positioning could be dictated by any windows or doors placed in elevation.

When intermediate lateral restraints are introduced, and it is not possible due to the columns, buckling resistance determines the sectional size selection initially. Therefore, it’s crucial to assess at the early stage whether side rails should be used to provide restraint to the columns.

Continuous side rails are the only type that is effective in providing such restraints. Any side rails that have been interrupted by shutter doors, for example, shouldn’t be relied on as they do not provide the right level of restraint.

Where the compression flange, rafter, or column isn’t restrained using purlins and side rails, alternative restraint can be provided using a column and rafter that stays on the inside flange.

Actions

Advice on actions is located in BS EN 1991. You can also find a combination of actions listed in BS EN 1990. It is very important that you use the UK National Annex for the necessary Eurocode part in order to commence with the construction of such structures in the U.K.

Permanent actions

Permanent actions refer to the weight of the structure itself, any secondary steelwork and external classing. Unit weights of all materials used across construction should be considered and obtained from each of the manufacturer’s data. If information cannot be located, such data can be found in BS EN 1991-1-1.

Service loads

Service loads always vary depending on the use of the building that is being constructed. In any portal frame, heavy point loads can occur from the use of suspended walkways and other types of elevated structures. Therefore, it’s crucial to consider with care where any additional provision may be required.

It depends on the use of the building itself, and if sprinklers are required in its construction, however, it is normal to account for a load of 0.1–0.25 kN/m2 on plan over the whole area of the roof.

Variable actions

Imposed roof loads

Any imposed loads that are placed on roofs are accounted for in the U.K. NA to BS EN 1991-1-1. However, it will be based on the roof slope itself. A point load, Qk is given, which is utilised for local checking of roof fixings and materials and a uniformly distributed load, qk, should be applied vertically. Note that in the case of imposed loads on roofs, there should never be a combination of wind or snow.

Snow loads

Snow loads can sometimes be used to determine the dominant gravity loading. A snow load’s value should be calculated using BS EN 1991-1-3 and its U.K. National Annex. In order to accurately determine a snow load, it is also advisable to refer to Chapter 3 of the Steel Designers’ Manual.

Any drift condition must be allowed not only in the design of the frame itself but also in the design of the purlins, which provide support for roof cladding. The severity of loading, along with the position of maximum drift, will usually exceed the basic minimum snow load.

Wind action

Determining wind action is crucial, and it can be determined by referring to BS EN 1991-1-4 and its U.K. National Annex. The Eurocode will provide a large amount of scope for any adjustments that must be made, and its annex is an important document.

Wind action is always complex and, without a doubt, will influence any final design of a building. Therefore, the designer must make a considered choice when they assess wind actions and choose appropriate ways to simplify a design process. This also must include conservative load bearing.

Crane actions

The most utilised crane for any type of building construction is an overhead crane which runs on beams that are supported using columns. Beams are carried using cantilever brackets or, where they are heavier than usual, dual columns. Because of the weight of the cranes themselves and accompanying loads, effects of acceleration must be considered by a designer. In the case where simple cranes are used, a quasi-static approach can be used alongside amplified loads.

Accidental actions

Many common design situations are classified as accidental design situations and include:

- Drifted snow which can be determined using Annex B of BS EN 1991-1-3;

- Dominant openings that have been opened which were assumed to be shut at ULS.

Every project must be thoroughly assessed as to whether any sort of accidental actions could act on the structure itself.

Robustness

Robustness requirements are in place to ensure that no structural collapse is out of proportion to its cause. BS EN 1990 outlines and sets the requirements in order to design and construct any robust buildings with the prevention of disproportionate collapse under accidental design situations. BS EN 1991-1-7 provides the reader with details of how this requirement can be accurately met.

Fire

By law in the U.K., structural steel present in single-storey buildings does not normally need fire resistance. However, the most common scenario in which it is required to fire protect the structural steelwork is seen where preventing fire spread to adjacent buildings, referred to as a boundary condition, is needed. There are also a few other examples where this applied. For example, when demanded by an insurance provider.

If a portal frame is close to a boundary, there are a number of requirements that are aimed at preventing fire spread by ensuring that the boundary is intact:

- Use of fire-resistant cladding

- The Application of fire protection of the steel up to the underside of the haunch

- The provision of a moment resisting base

Full, comprehensive advice can be found in SCI P313.

Combinations of actions

BS EN 1990 provides the lawful rules for establishing combinations of actions. It considers the values of relevant factors provided in the U.K. National Annex. BS EN 1990. It also covers both the ultimate limit state (ULS) and serviceability limit state (SLS), although for the SLS, onward reference is accounted for with material codes (for example BS EN 1993-1-1 for steelwork), which identifies the expression that should be used along with any observations.

All action combinations need to be considered, and if certain actions cannot be applied in some cases, the actions cannot be applied at once.

Further guidance on the application of Eurocode rules and combinations of actions can be located in SCI P362 and, specifically for portal frames, in SCI P399.

Sources for further information:

https://steelconstruction.info/Portal_frames

https://en.wikipedia.org/wiki/Portal_frame

https://www.wiley.com/en-gb/Steel+Designers%27+Manual%2C+7th+Edition-p-9781119249863